jay@nbdho.com

Detailed Customization Process for Genuine Leather Jewelry Boxes

Detailed Customization Process for Genuine Leather Jewelry Boxes

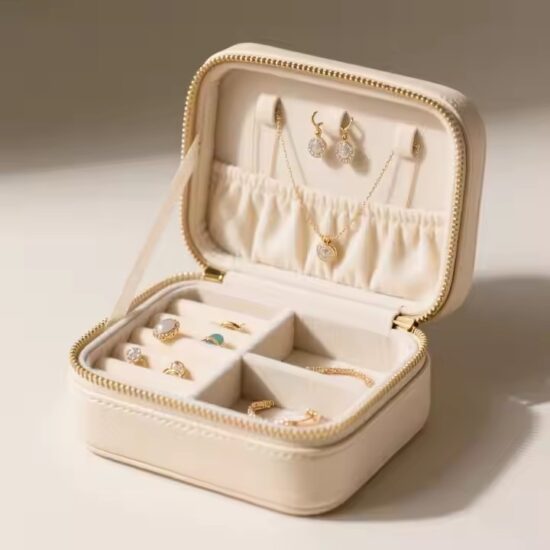

Customizing genuine leather jewelry boxes allows brands and individuals to create packaging that perfectly reflects their style, values, and the precious items inside. From design conception to final production, a well-structured customization process ensures quality, uniqueness, and customer satisfaction.

Here’s a detailed overview of the customization journey for genuine leather jewelry boxes.

1. Initial Consultation and Design Brief

-

Discuss your brand vision, style preferences, and functional requirements

-

Determine box size, compartments, and interior layout based on jewelry types

-

Choose design elements such as colors, textures, embossing, or printing

-

Consider sustainability preferences, such as eco-friendly leather or linings

Clear communication sets the foundation for a successful custom project.

2. Material Selection

-

Select the type and grade of genuine leather: full-grain, top-grain, or corrected grain

-

Choose interior lining materials like velvet, microfiber, or suede for protection and luxury feel

-

Decide on hardware options such as magnetic clasps, hinges, or locks

-

Confirm eco-certifications or special finishes if required

Material choices impact both aesthetics and durability.

3. Prototype Development

-

Create digital mockups or physical samples based on design inputs

-

Review leather texture, color accuracy, stitching quality, and overall feel

-

Make adjustments as needed for fit, finish, or functional details

-

Approve prototype before moving to mass production

Prototyping minimizes errors and aligns expectations.

4. Production and Craftsmanship

-

Skilled artisans cut, stitch, and assemble leather pieces with precision

-

Leather is carefully wrapped around rigid box bases, ensuring tight, wrinkle-free surfaces

-

Interior linings are added and compartments installed according to design

-

Hardware components are attached and tested for durability and function

High-quality craftsmanship ensures a premium final product.

5. Quality Control

-

Inspect every box for leather consistency, stitching neatness, and hardware function

-

Check for defects, discoloration, or surface blemishes

-

Confirm interior finishing is smooth and secure

-

Test closures and hinges for smooth operation

Strict quality control guarantees product reliability and brand reputation.

6. Packaging and Delivery

-

Boxes are carefully packed to prevent damage during shipping

-

Custom packaging or branding (e.g., boxes with logos or ribbons) can be added

-

Delivery timelines are confirmed and tracked

-

After-sales support is provided for any issues or reorders

Attention to detail in logistics completes the customization experience.

📦 Conclusion

The customization process for genuine leather jewelry boxes is a blend of creativity, material expertise, and craftsmanship. By following these detailed steps, brands and customers receive bespoke packaging that enhances product value, protects precious jewelry, and offers a unique unboxing experience.

Partnering with a professional supplier ensures that your vision is realized with precision and quality.